Mycom B DV Assembly

Mycom B DV Assembly Specification

- Frequency

- 50 Hz / 60 Hz

- Motor Power

- 10 to 100 HP (varies with model)

- Weight

- Approx. 180 kg - 800 kg (model dependent)

- Noise Level

- 70-85 dB (depending on model and installation)

- Power Rating

- As per Model

- Filtration Grade

- Industrial Grade

- Refrigerant Type

- R22 / R404A / R507A

- Flow Rate

- Up to 350 m/h

- Pressure Capacity

- Up to 22 bar

- Cooling Method

- Water Cooled

- Control System

- Manual/Automatic

- Phase

- Three Phase

- Drive Type

- Belt Driven

- Type Of Compressor

- Reciprocating Compressor

- Allied Equipment

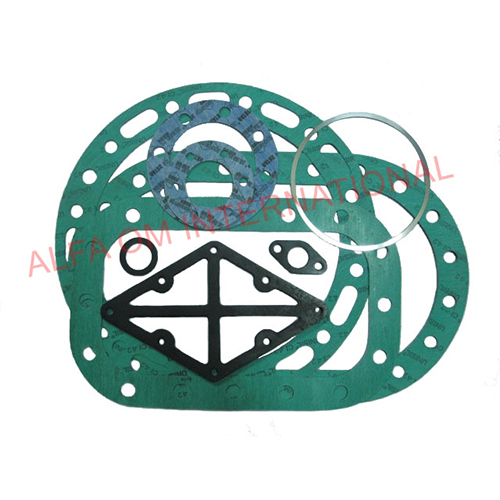

- DV Assembly

- Configuration

- Base Mounted

- Power Source

- Electric

- Silent

- No

- Lubrication Type

- Oil Lubricated

- Voltage

- 380-415 V

- Driven Mode

- Belt Drive

- Available Models

- MYCOM B80, B100, B150, B200, B220, B250, etc.

- Discharge Connection

- Flanged / Screwed

- Serviceability

- Easy Maintenance and Overhaul

- Mounting Type

- Horizontal / Base Mounted

- Port Size

- As per Compressor Model

- Material of Construction

- High Grade Cast Iron / Steel

- Applicable Industries

- Cold Storage, Refrigeration Plants, Food Processing

- Temperature Range

- -45°C to +10°C

- Standards Compliance

- ISO 9001 Certified Components

About Mycom B DV Assembly

Mycom B DV Assembly is an assembly of components used in the assembly of the Mycom B DV. It consists of a motherboard, a processor, a heat sink, a fan, a power supply, a hard drive, a CD/DVD drive, a graphics card, a sound card, and a USB port. The assembly process begins with the installation of the motherboard. The processor, heat sink, and fan are then installed onto the motherboard. The power supply, hard drive, CD/DVD drive, and graphics card are then installed onto the motherboard. The sound card and USB port are then connected to the motherboard. Finally, the assembly is complete and the Mycom B DV is ready to be used.High Performance and Versatility

The Mycom B DV Assembly delivers consistent results in refrigeration and cold storage environments. Its robust construction allows operation across wide temperature ranges, making it suitable for diverse industrial sectors. With a choice of models and configurations, users can select equipment that matches their specific cooling and capacity needs.

Easy Maintenance and Reliability

Built for longevity, this compressor assembly utilizes high-grade materials and is engineered for straightforward servicing. The horizontal and base-mounted design ensures accessible installation and smoother overhauls, reducing downtime and facilitating regular maintenance. ISO 9001 certification guarantees quality and reliability for long-term use.

FAQ's of Mycom B DV Assembly:

Q: How can the Mycom B DV Assembly be installed in my facility?

A: The unit is designed for horizontal or base mounting, making it adaptable to existing compressor setups in cold storage or food processing plants. Professional technicians should follow manufacturer guidelines to ensure proper installation and system compatibility.Q: What industries commonly use the Mycom B DV Assembly?

A: This compressor assembly is widely utilized in cold storage, refrigeration plants, food processing, and other related industries where robust refrigeration and temperature control are critical.Q: When should routine maintenance and overhauls be performed?

A: Regular maintenance is recommended based on operational hours and manufacturer instructions. Typically, service intervals depend on usage intensity; easy-access design enables timely inspection, part replacement, and thorough overhauls to maintain efficiency.Q: Where can I source spare parts and support for this equipment?

A: As an exporter, manufacturer, supplier, and trader based in India, the company offers comprehensive support and genuine spare parts for all available models. Customers can contact local representatives for assistance and part procurement.Q: What are the benefits of choosing ISO 9001 certified components?

A: ISO 9001 certified components assure consistent quality, safety, and performance. Choosing certified assemblies reduces the risk of unexpected failures and ensures that the compressor meets industry standards for reliability.Q: How does the compressor accommodate various refrigerants and flow rates?

A: The Mycom B DV Assembly supports multiple refrigerants, including R22, R404A, and R507A, across a wide pressure and flow rate range, up to 350 m3/h. Model selection allows users to match system requirements for optimal cooling and efficiency.Q: What safety and control options are included with the assembly?

A: Control systems are available in manual or automatic configurations, and filtration is industrial grade, supporting operational safety and consistent performance. Discharge connections can be flanged or screwed, catering to varied installation needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mycom Compressor Spare Parts Category

Mycom B Connecting Rod

Lubrication Type : Not available, Other

Type Of Compressor : Not available, Other

Driven Mode : Not available

Allied Equipment : Not available, Other

Weight : Not available

Refrigerant Type : Not available

Mycom B Double Collar Assy

Lubrication Type : Other, Oil Lubricated

Type Of Compressor : Other, Reciprocating Compressor (Mycom B Series)

Driven Mode : Shaft Driven

Allied Equipment : Other, Double Collar Assembly

Weight : Approx. 2.85 kg

Refrigerant Type : Compatible with R22, NH3, HFCs

Mycom A Single Collar Seal Assy

Lubrication Type : Other, Oil Lubricated

Type Of Compressor : Reciprocating

Driven Mode : Mechanical

Allied Equipment : Other, Seal Assembly

Weight : Approx. 24 Kg

Refrigerant Type : Compatible with Mycom compressors

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry