Call: 08071630547

Mycom B Thrust Bearing

Mycom B Thrust Bearing Specification

- Weight

- Standard

- Refrigerant Type

- Compatible with standard refrigerants

- Noise Level

- Standard

- Type Of Compressor

- Reciprocating Compressor

- Allied Equipment

- Thrust Bearing

- Configuration

- B Series

- Silent

- No

- Lubrication Type

- Oil Lubricated

- Driven Mode

- Mechanical

- Color

- Silver/Metallic

- Usage

- Provides axial and radial load support

- Dimensions

- OEM standard, varies by compressor model

- Product Name

- Mycom B Thrust Bearing

- Application

- For Mycom compressor B series

- Shape

- Round

- Surface Treatment

- Polished

- Resistance

- Corrosion and wear resistant

- Material

- Alloy steel

- Finish

- Precision finished and hardened

About Mycom B Thrust Bearing

Mycom B thrust bearings are designed specifically for high axial loads, and are typically found in gas turbine engines, turbochargers, and other high-speed, heavy-duty applications. These bearings are usually cylindrical in shape, with a thrust collar and a shaft collar. They are designed to support axial loads without excessive friction, and to keep the shaft from spinning or moving in the bearing. Mycom B thrust bearings are designed to be highly reliable, durable and able to withstand high temperatures and pressures. They are typically made from high-grade steel and are available in a variety of sizes, shapes and configurations.Superior Durability and Reliability

Crafted from high-grade alloy steel and precision finished, the Mycom B Thrust Bearing delivers consistent durability and wear resistance even in rigorous compressor applications. Its hardened surface extends operational life and minimizes maintenance needs, making it a dependable choice for industrial environments.

Optimized for Mycom B Series Compressors

Specifically designed to meet the OEM specifications of Mycom compressor B series, this thrust bearing ensures proper fit and flawless performance. Its round shape and customizable dimensions accommodate various compressor models, supporting both axial and radial loads for optimal functioning.

Corrosion and Wear Resistance

The bearing's polished and hardened surface treatment provides robust protection against corrosion and wear. This not only safeguards the internal mechanisms of the compressor but also enhances reliability in demanding conditions, contributing to long-term efficiency.

FAQ's of Mycom B Thrust Bearing:

Q: How is the Mycom B Thrust Bearing installed in compressors?

A: The Mycom B Thrust Bearing is designed for seamless integration into the compressor's mechanical configuration. Installation involves proper alignment with the compressor's shaft and ensuring secure placement to facilitate effective axial and radial load support.Q: What is the function of the thrust bearing in a Mycom B series compressor?

A: Its primary role is to support both axial and radial loads, reducing wear and friction during the compressor's mechanical operation. This helps ensure smoother performance and prolongs the life of the compressor components.Q: When should the Mycom B Thrust Bearing be replaced?

A: Replacement is recommended during routine maintenance if there are signs of increased noise, vibration, or reduced compressor efficiency. Physical wear or damage to the bearing also indicates a need for replacement to avoid further issues.Q: Where can I source genuine Mycom B Thrust Bearings in India?

A: You can obtain authentic Mycom B Thrust Bearings from reputable exporters, manufacturers, suppliers, and traders specializing in compressor components across India. Verify OEM compatibility before purchase for optimal performance.Q: What process ensures the bearing's excellent resistance properties?

A: The bearing undergoes precision finishing, hardening, and polishing during manufacturing, which enhances its ability to resist corrosion and wear. These treatments uphold reliability even in demanding environments with standard refrigerants.Q: How does oil lubrication benefit the thrust bearing's operation?

A: Oil lubrication minimizes friction and heat generation, resulting in smoother movement within the compressor. This extends the bearing's lifespan and maintains consistent compressor function, reducing maintenance intervals.Q: What are the benefits of using the Mycom B Thrust Bearing in reciprocating compressors?

A: Utilizing this thrust bearing brings operational stability, improved load management, and extended service life to reciprocating compressors. Its durable construction and resistance properties contribute to efficient, long-term compressor performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Mycom Compressor Spare Parts Category

Mycom B Connecting Rod

Configuration : Not available, Other

Weight : Not available

Drive Type : Other, Not available

Lubrication Type : Not available, Other

Driven Mode : Not available

Pressure Capacity : Not available

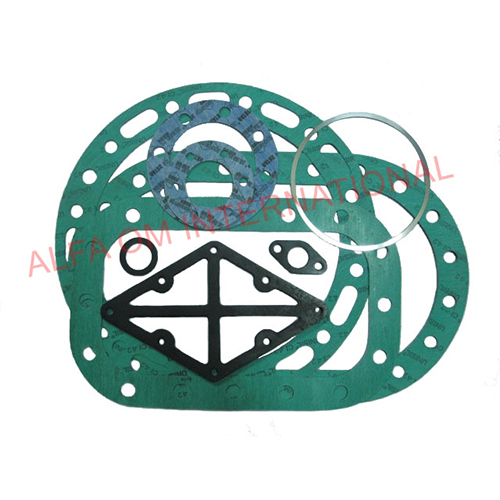

Mycom B Valve Plate

Configuration : Stationary

Weight : Approx. 12 Kg

Drive Type : Other, Belt Drive

Lubrication Type : Other, Oil Lubricated

Driven Mode : Belt Driven

Pressure Capacity : Up to 25 Bar

Mycom B DV Assembly

Configuration : Other, Base Mounted

Weight : Approx. 180 kg 800 kg (model dependent)

Drive Type : Other, Belt Driven

Lubrication Type : Other, Oil Lubricated

Driven Mode : Belt Drive

Pressure Capacity : Up to 22 bar

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry